Soluciones innovadoras con

el mínimo impacto medioambiental

La depuración de las aguas residuales, se basa en eliminar todos los residuos que ha ido acumulando el agua residual, y devolverla al medio con las condiciones óptimas, para proteger los ecosistemas acuáticos, evitar riesgos para la salud pública y obtener agua apta para su reutilización. Así se asegura el futuro de próximas generaciones y del medioambiente, logrando un desarrollo sostenible.

En el Municipio de Torrevieja se dispone una estación depuradora de agua residual (EDAR) con capacidad de tratamiento actual de 60.000 m³/día, para dar servicio a 490.000 habitantes equivalentes, mejorando la calidad del efluente con tratamiento terciario.

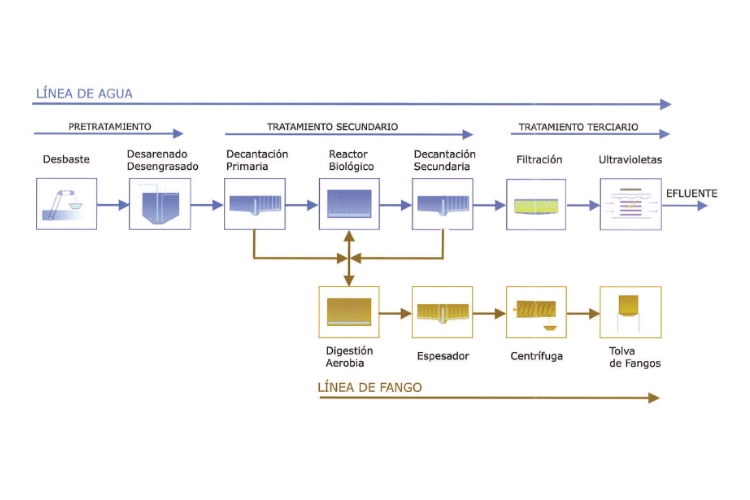

La instalación consta de: pretratamiento, homogenización, decantación primaria, tratamiento biológico, decantación secundaria y tratamiento terciario con desinfección, completándose la línea de agua con un tratamiento de los lodos generados a base de digestión anaerobia, espesamiento y deshidratación.

Actualmente el 100% del agua depurada es reutilizada para riego agrícola de comunidades de regantes.

Los lodos generados se emplean en aplicación agrícola como abono o bien son usados como combustible en el proceso de fabricación de los hormigones (valorización energética) en la planta de CEMEX de San Vicente del Raspeig.

-

Datos técnicos y características principales

- Proceso de tratamiento

Fangos activados en oxidación total Deshidratación con centrifugas de alta sequedad Destino final del efluente Riego agrícola Destino final de fangos Utilización como abono o valorización energética - Datos base

Capacidad de tratamiento 60.000 m3/día Población servida 490.000 habitantes equivalentes Rendimiento eliminación DB05 Superior al 99% Rendimiento eliminación SS Superior al 99% Rendimiento eliminación DQO Superior al 96% - Datos 2021

Agua Tratada 6.523.500 m3/año Habitantes equivalente servidos 136.158 Habitantes equivalentes Agua reutilizada para riego 6.428.424 m3/año Rendimiento de eliminación DBO5 Superior al 99% Rendimiento de eliminación SS Superior al 99% Rendimiento de eliminación DQO Superior al 97% Lodos aplicación agrícola 6.564 Tn/año Lodos valorización energética 2.460 Tn/año Residuos eliminados 0 Tn/año - Características principales

Rejas automáticas gruesos > 5 mm 4 Ud Tamizado automático sólidos finos > 2 mm 4 Ud Canales desarenado - desengrasado 3 Ud (375,5 m3) Capacidad balsa de homogeneización 7.500 m3 Bombas de impulsión 7 Ud Decantación primaria 3 Ud (2.290 m3/Ud) Reactores biológicos 3 Ud (9.720 m3) Equipos aereación 5 turbocompresores (12.500 Nm3/h) Deshidratación 3 centrífugas de 75 m3/h Desinfección 5 equipos de U.V. y dosificación de hipoclorito sódico Control automatizado Telemando Tratamiento terciario Compuesto por 9 lechos de arena de filtración rápida Clarificadores 6 Ud circulares de 2.700 m3/Ud Laboratorio central de control de procesos 1 Ud.